Plastic Injection Moulds

High-precision injection moulds for single and multi-component plastic parts.

A Plastic Injection Moulding Partner You Can Trust

At Hard Ferr, we design and manufacture high-performance plastic injection moulds and also produce complete, ready plastic components in-house using our own moulding machines. From rapid prototype tooling to multi-cavity production moulds, we support our clients from the earliest tooling requirements all the way through to finished, production-ready parts.

All tooling is manufactured at our Hungary facility using advanced CNC machining, EDM, and precision grinding equipment. We can produce moulds up to 5 tonnes and with overall dimensions up to 1,000 by 600 millimetres, giving us the capability to support both small and large, complex systems. Every tool is sampled, tested, and validated before delivery, with UK-based support ensuring clear communication throughout the entire process.

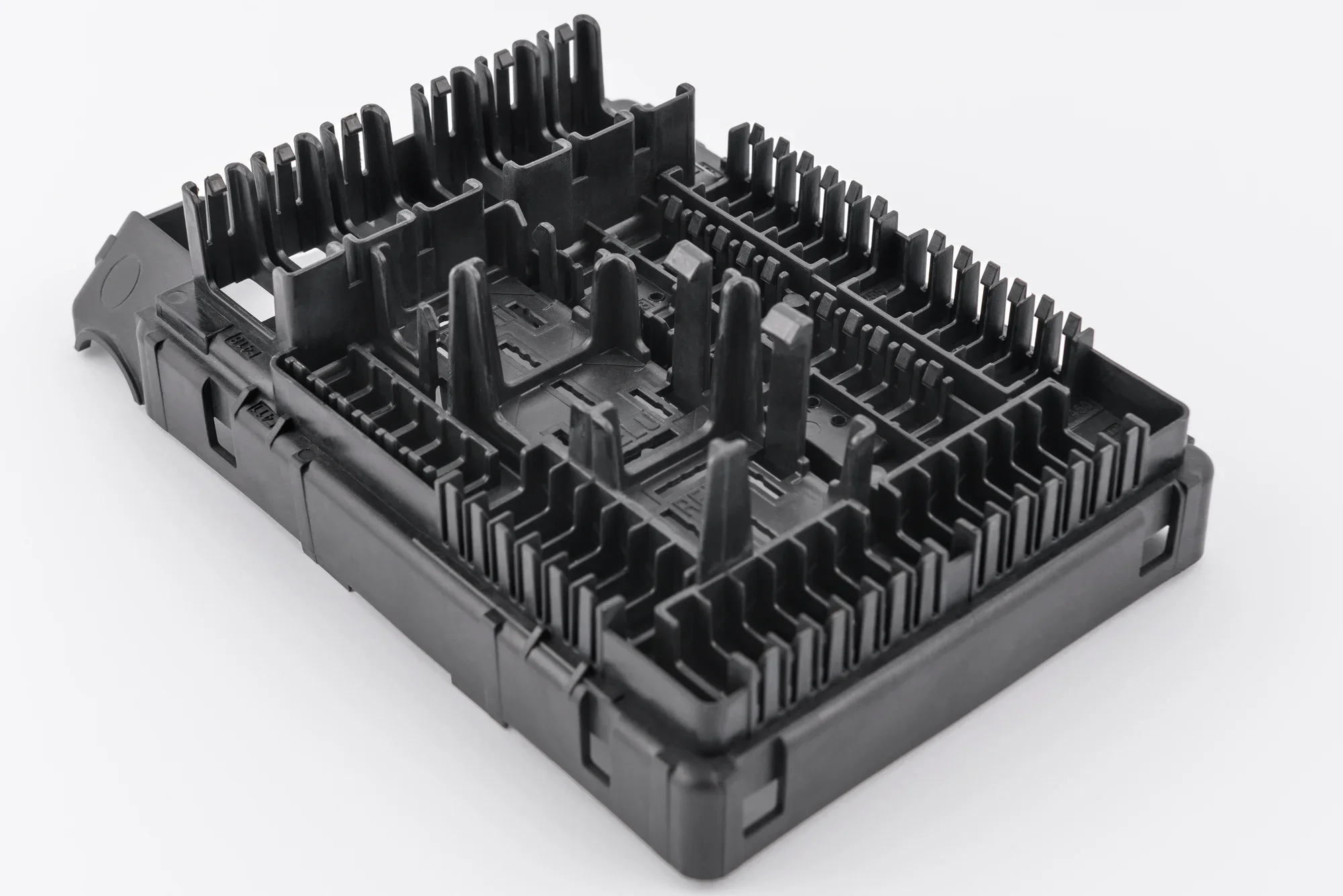

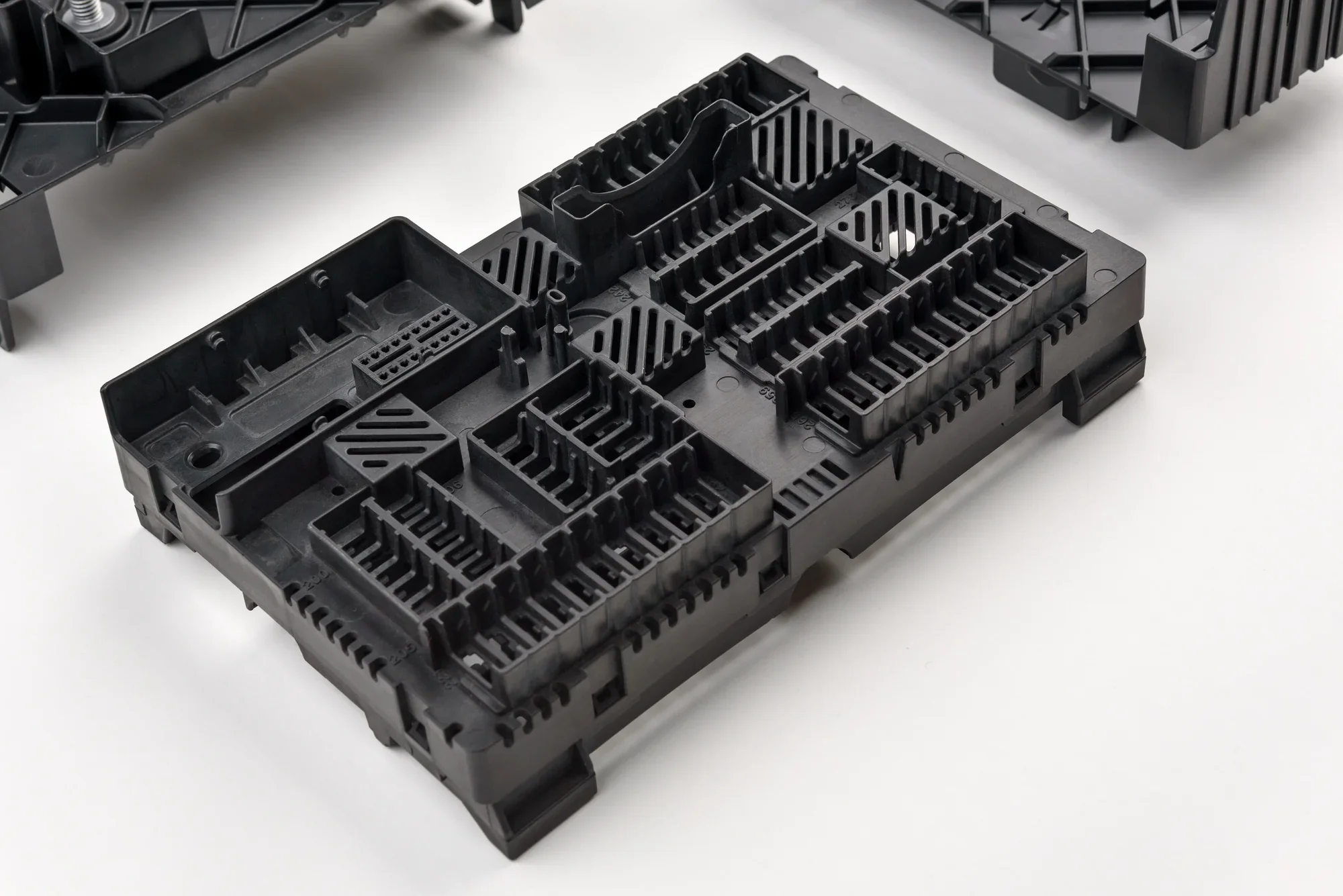

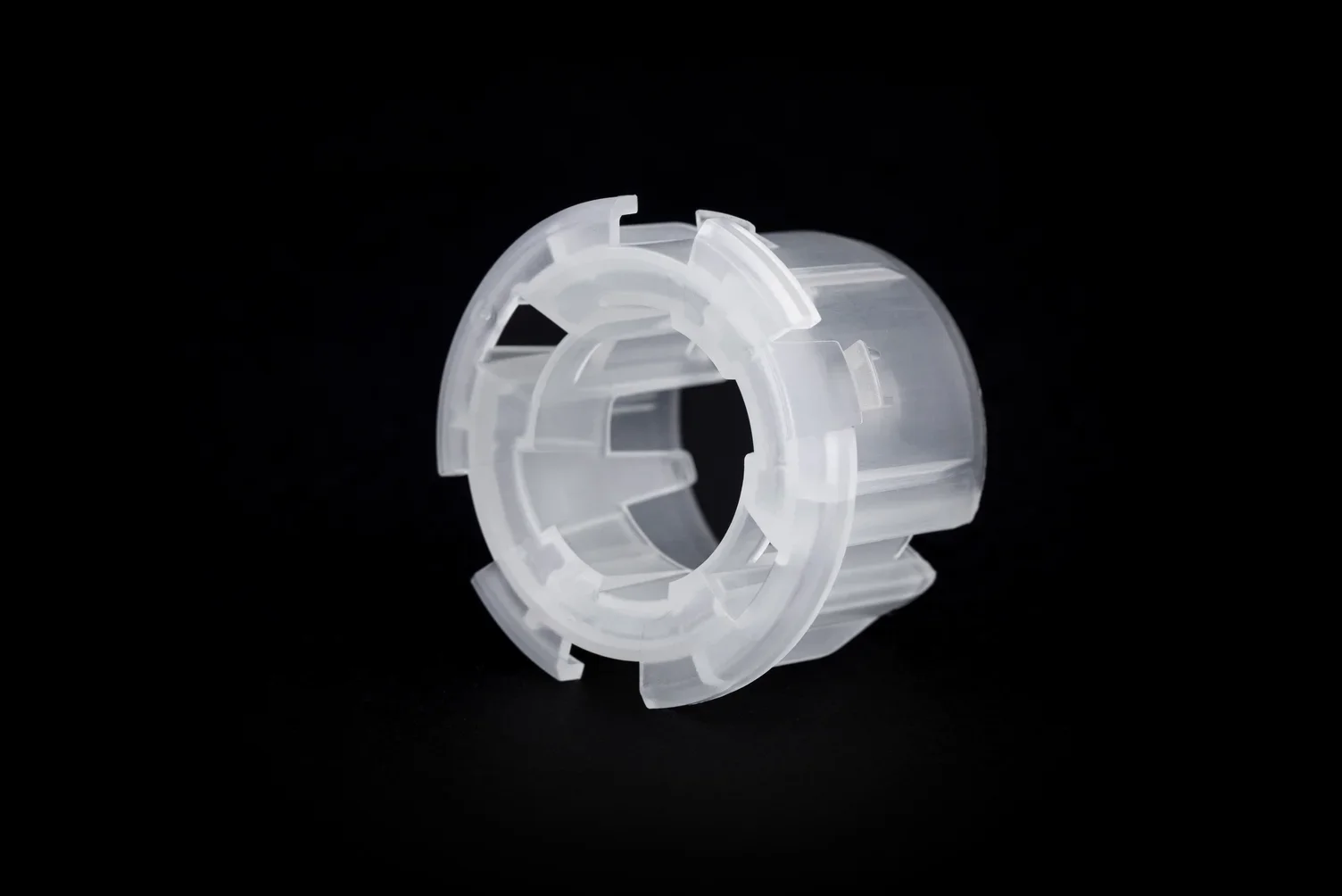

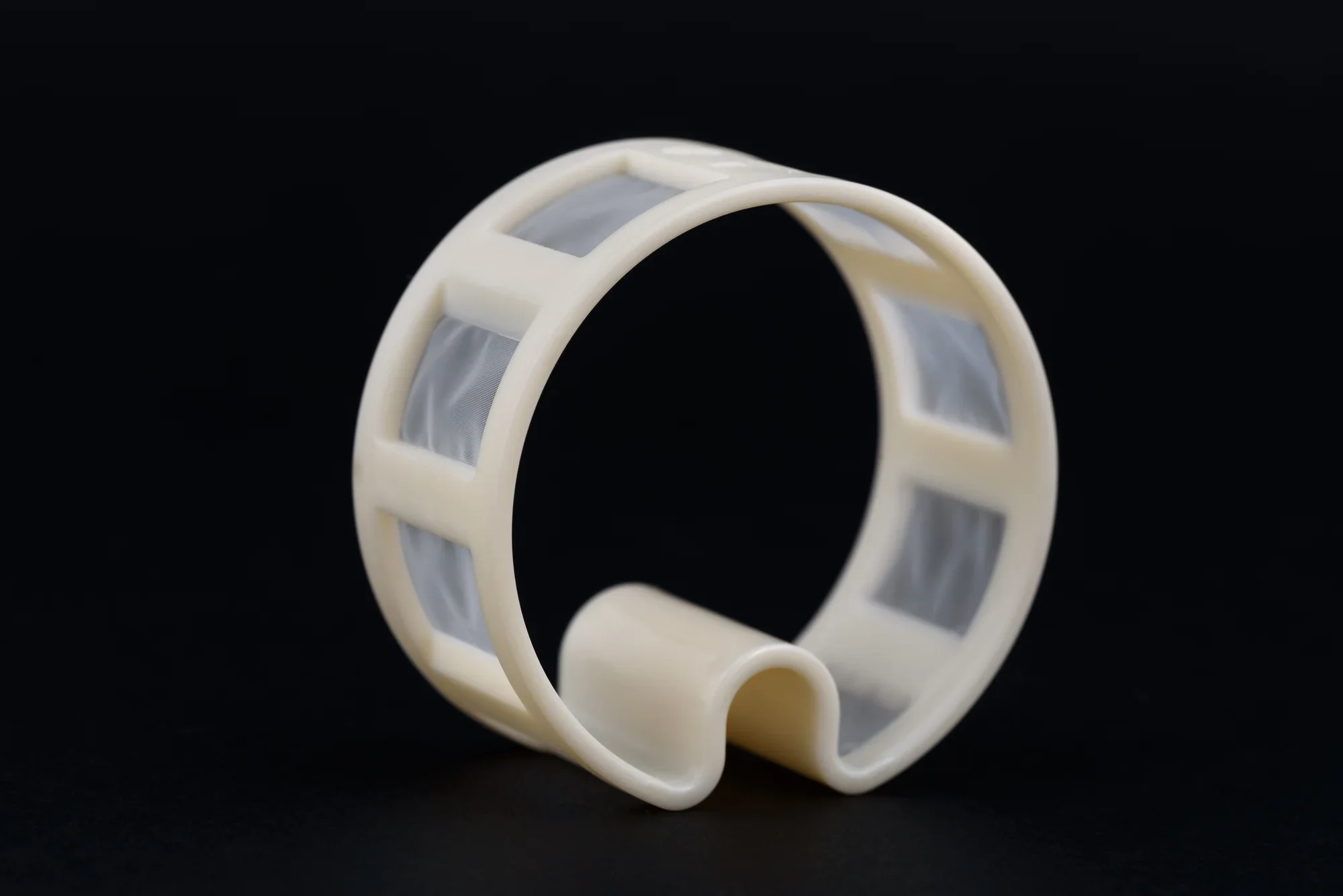

We produce a wide range of tooling including single and multi-cavity moulds, family tools, insert and overmould designs, and multi-component (2K and 3K) systems in both hot and cold runner configurations. Each mould is built from high-quality tool steels or specialist alloys to deliver long-term durability, stable cycle times, and consistent, repeatable performance.

What Components We Machine

We manufacture both the moulds and the final plastic components. Using our in-house injection moulding machines, we produce complete, ready parts that meet the exact specification, geometry, and performance requirements of each project.

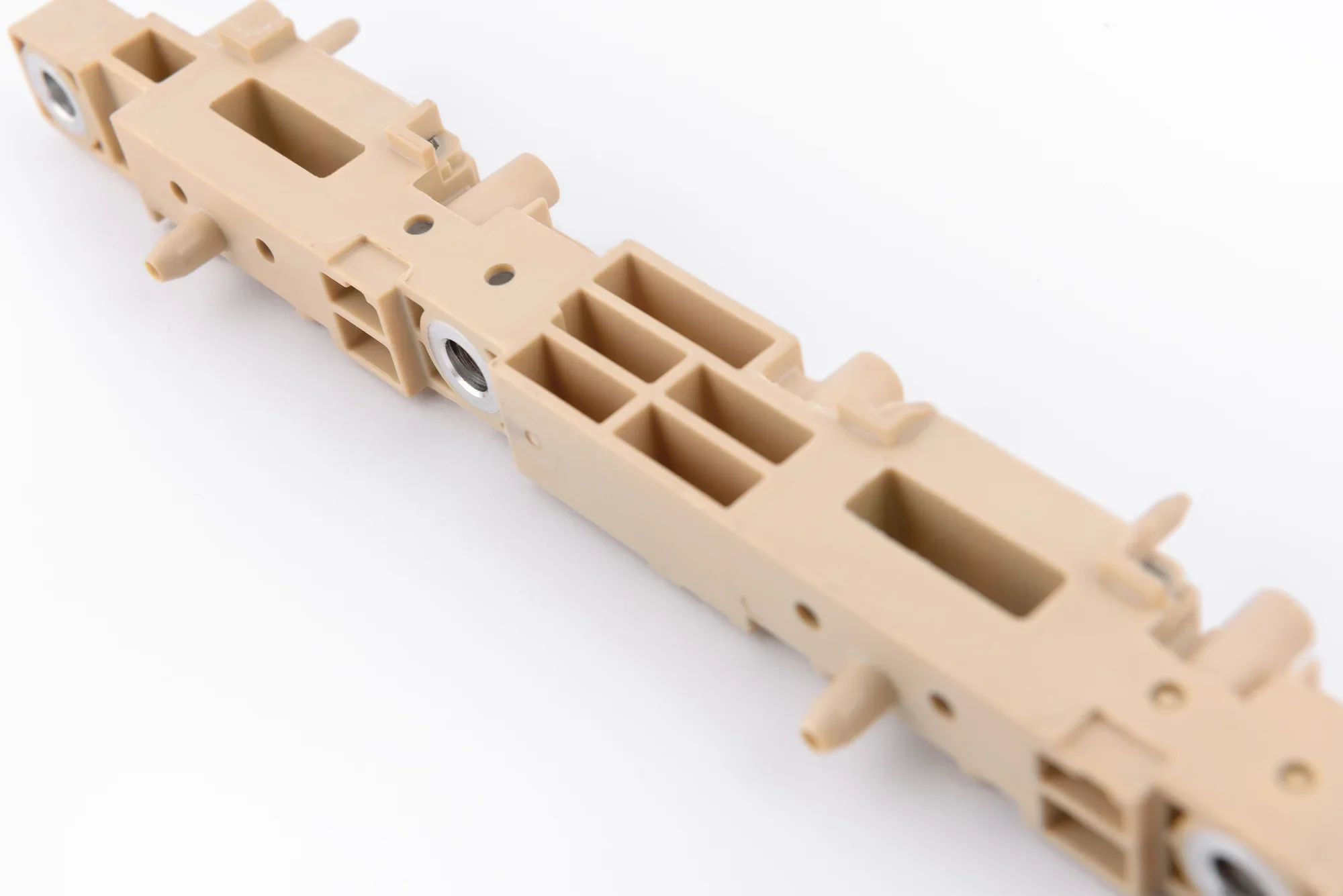

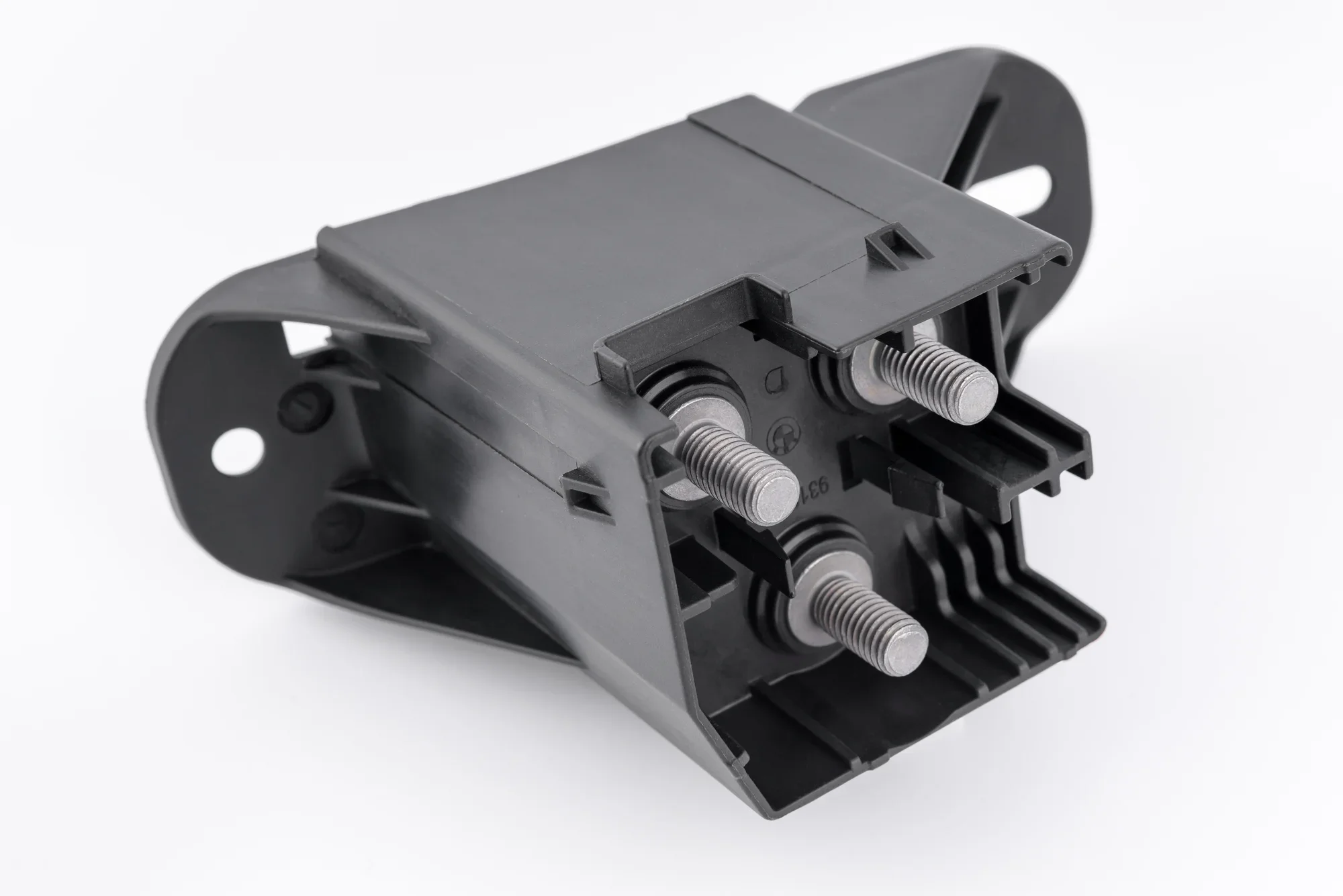

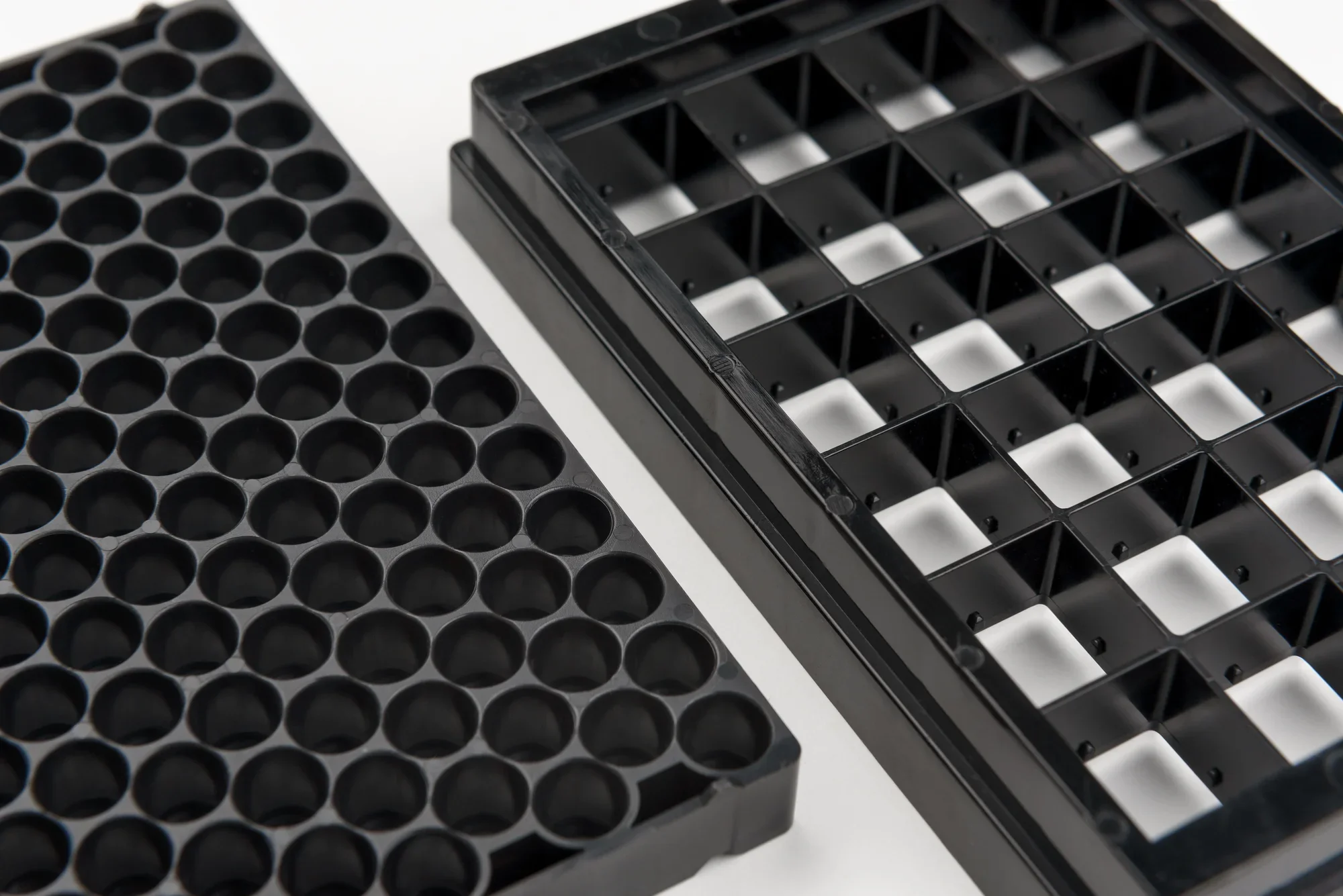

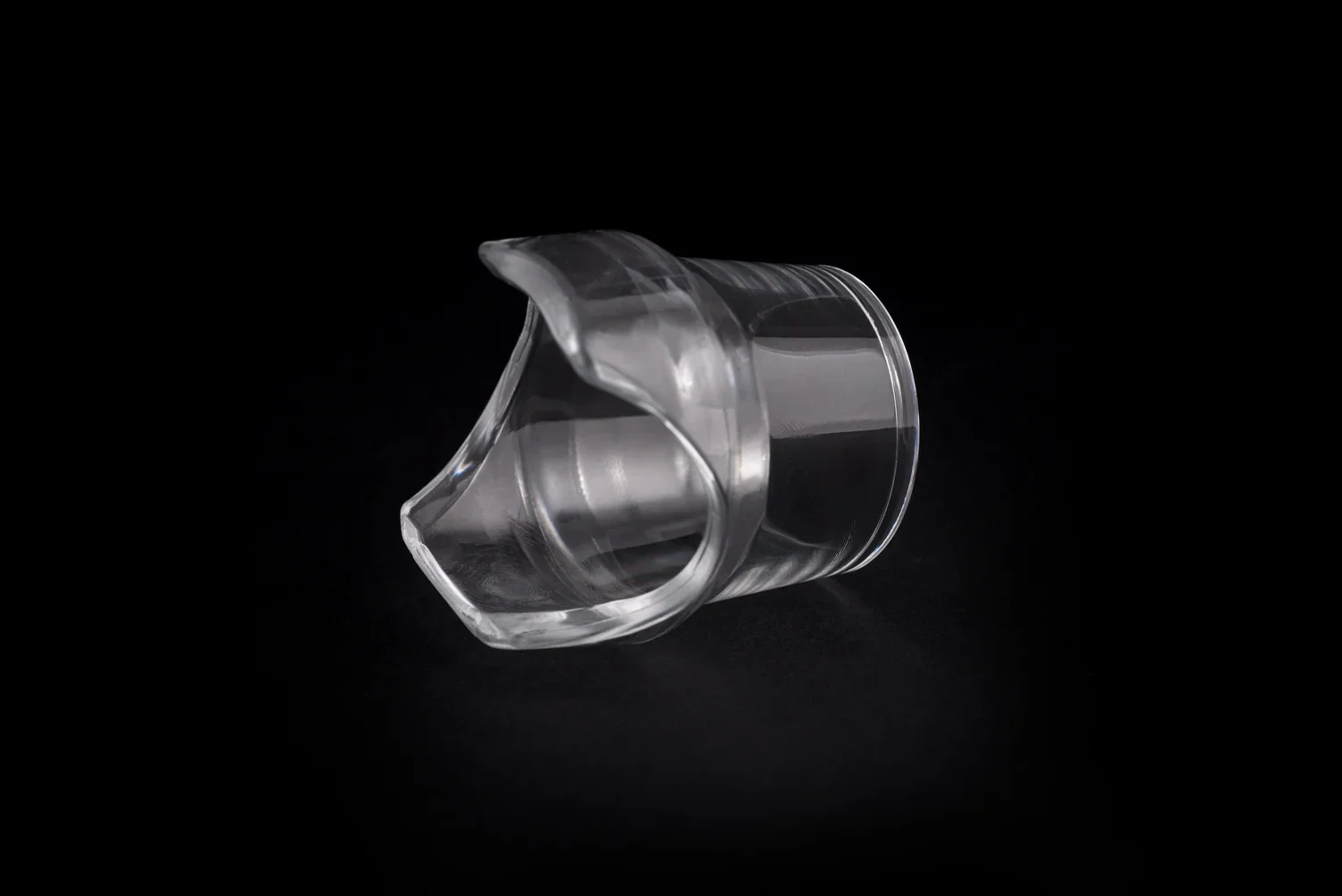

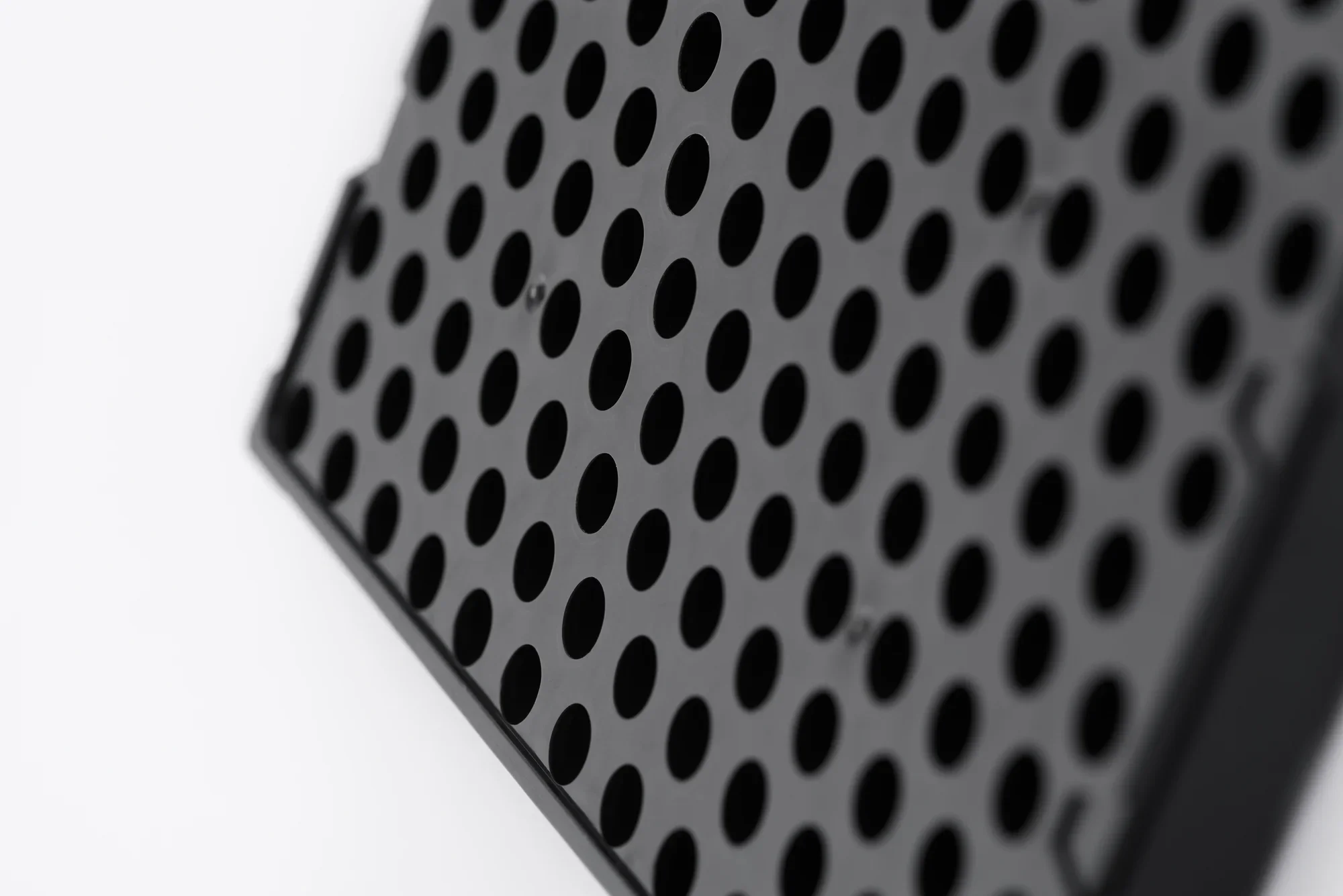

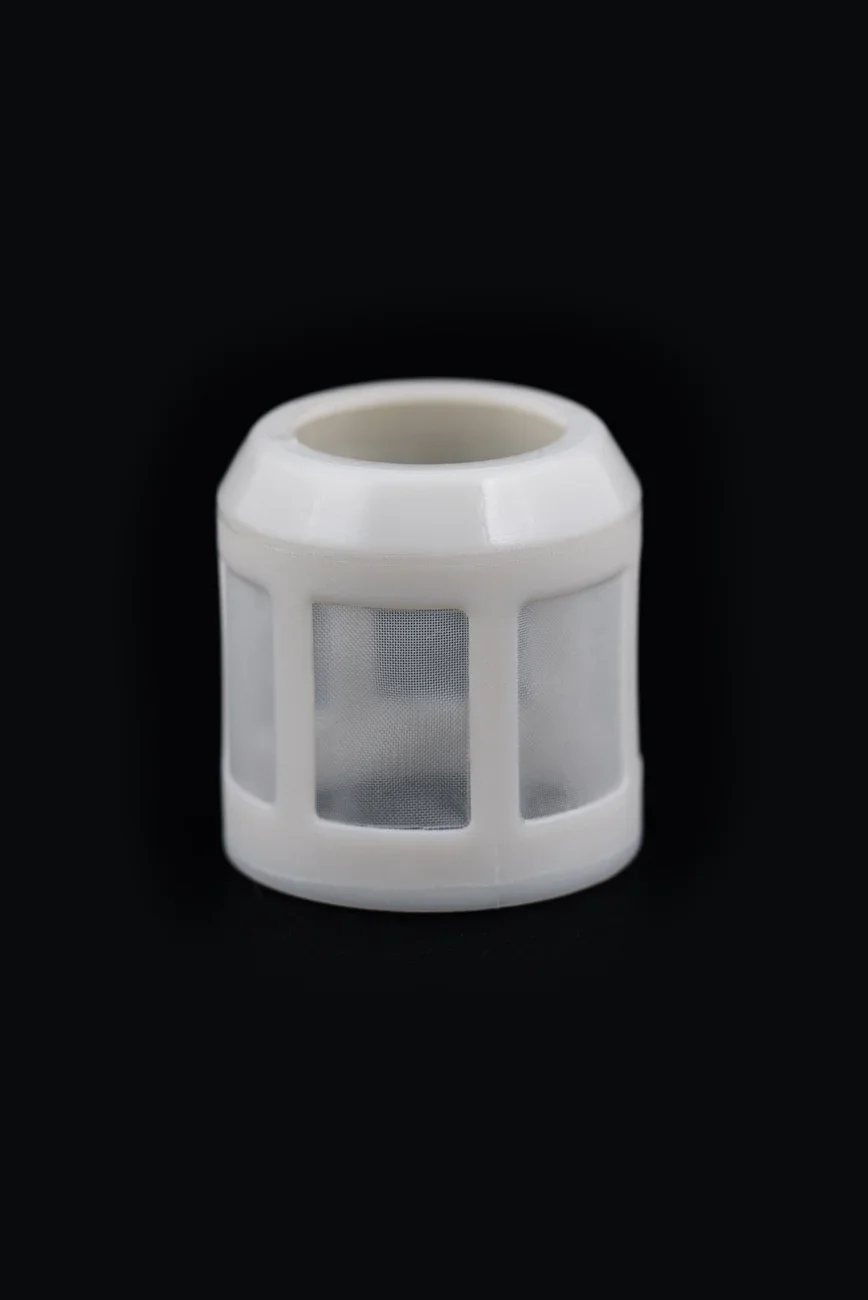

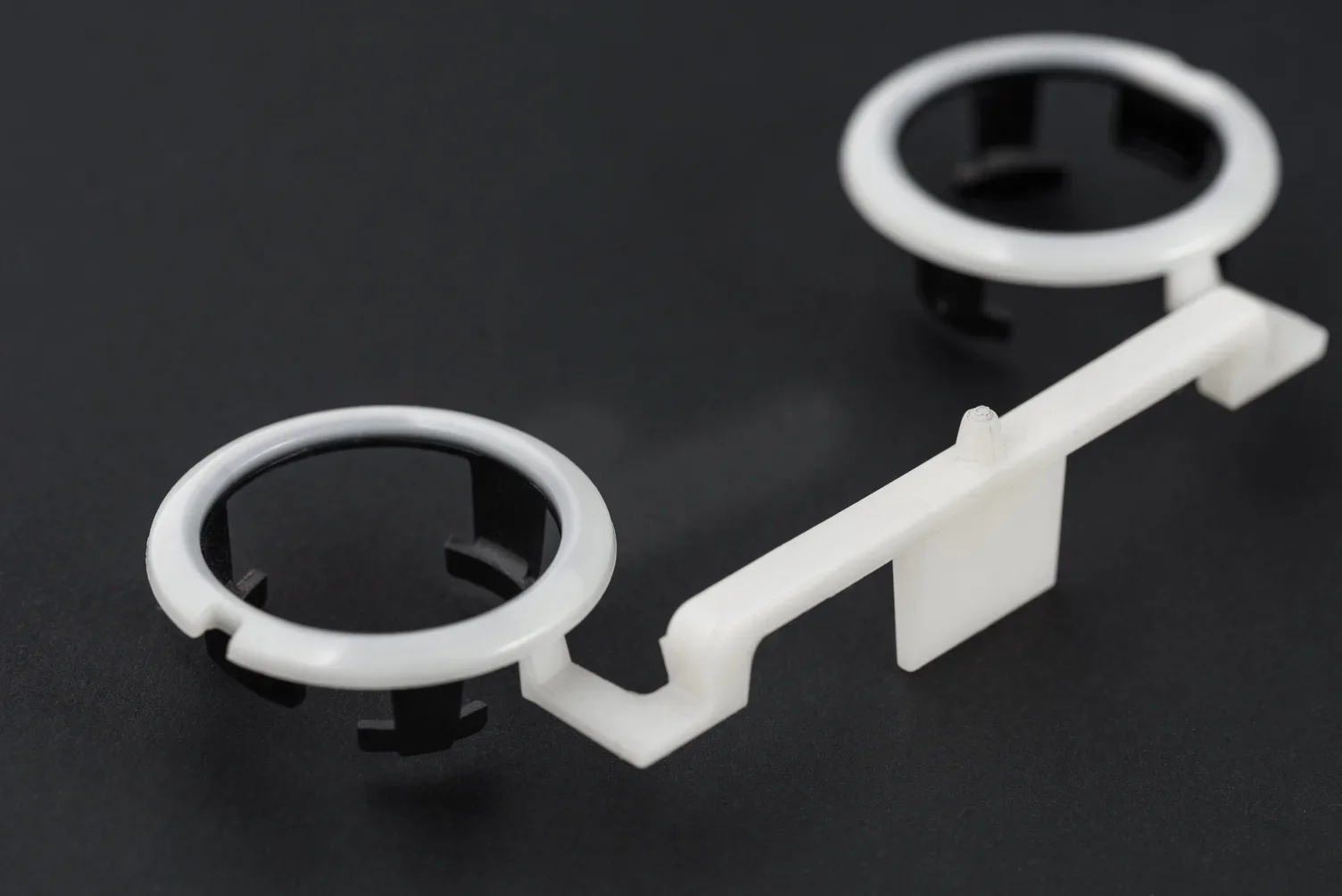

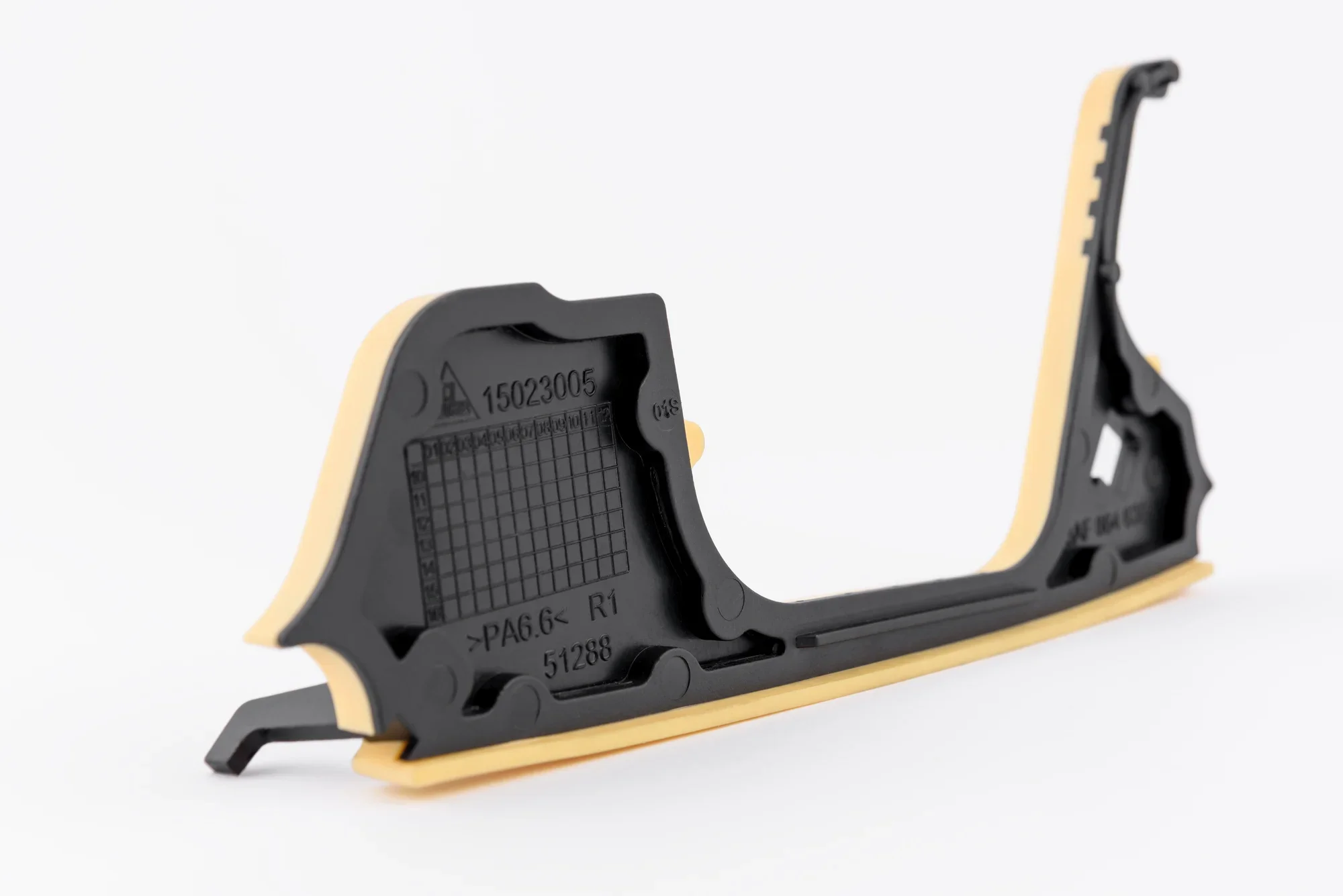

Our production supports a wide range of applications including medical and laboratory products, automotive interior and exterior components, consumer goods, baby products, threaded plastic parts, packaging products, appliance components, overmoulded parts, and multi-component (2K/3K) assemblies. Whether for large production volumes or specialised low-volume items, every mould and every part is built for accuracy, durability, and reliable long-term performance.

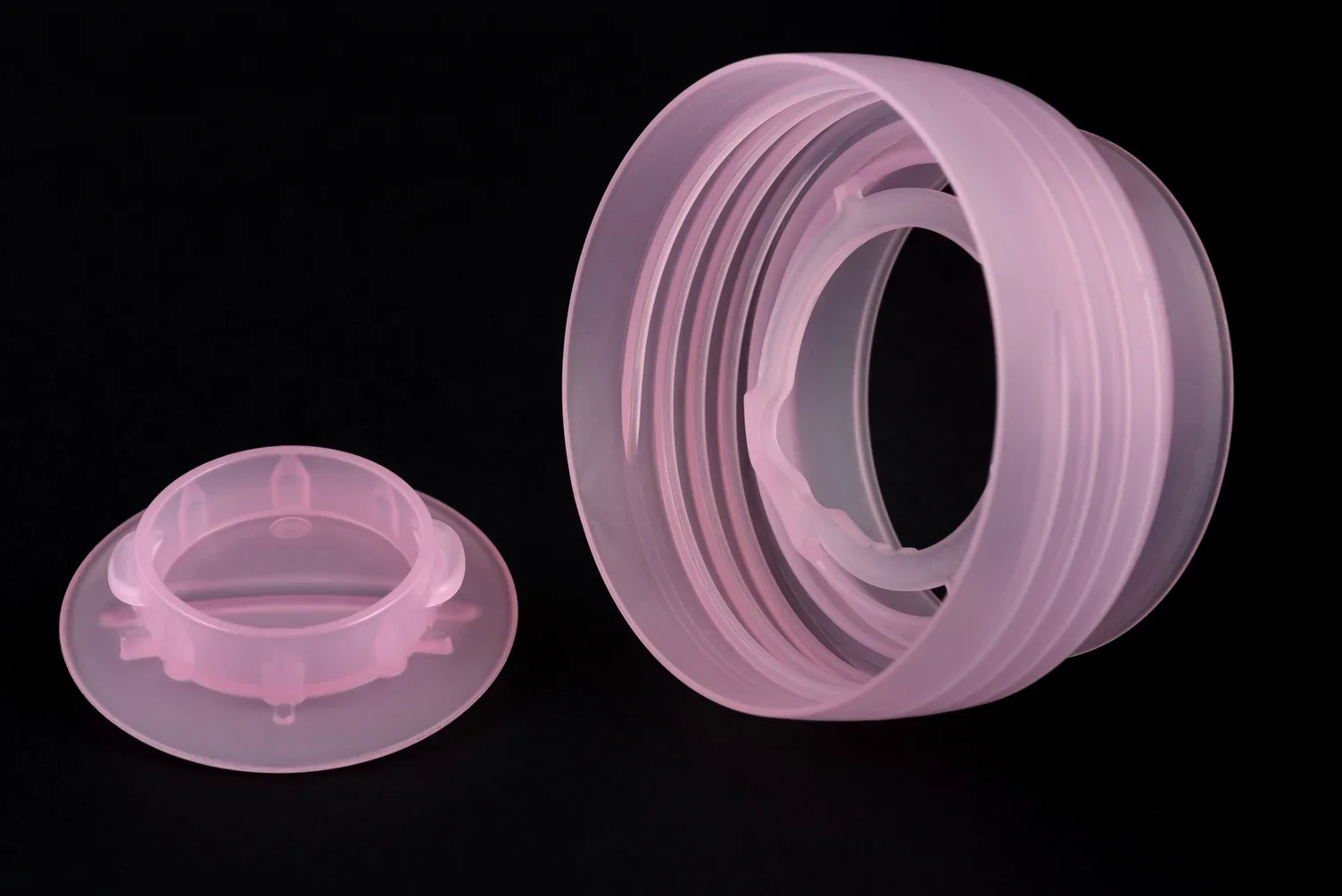

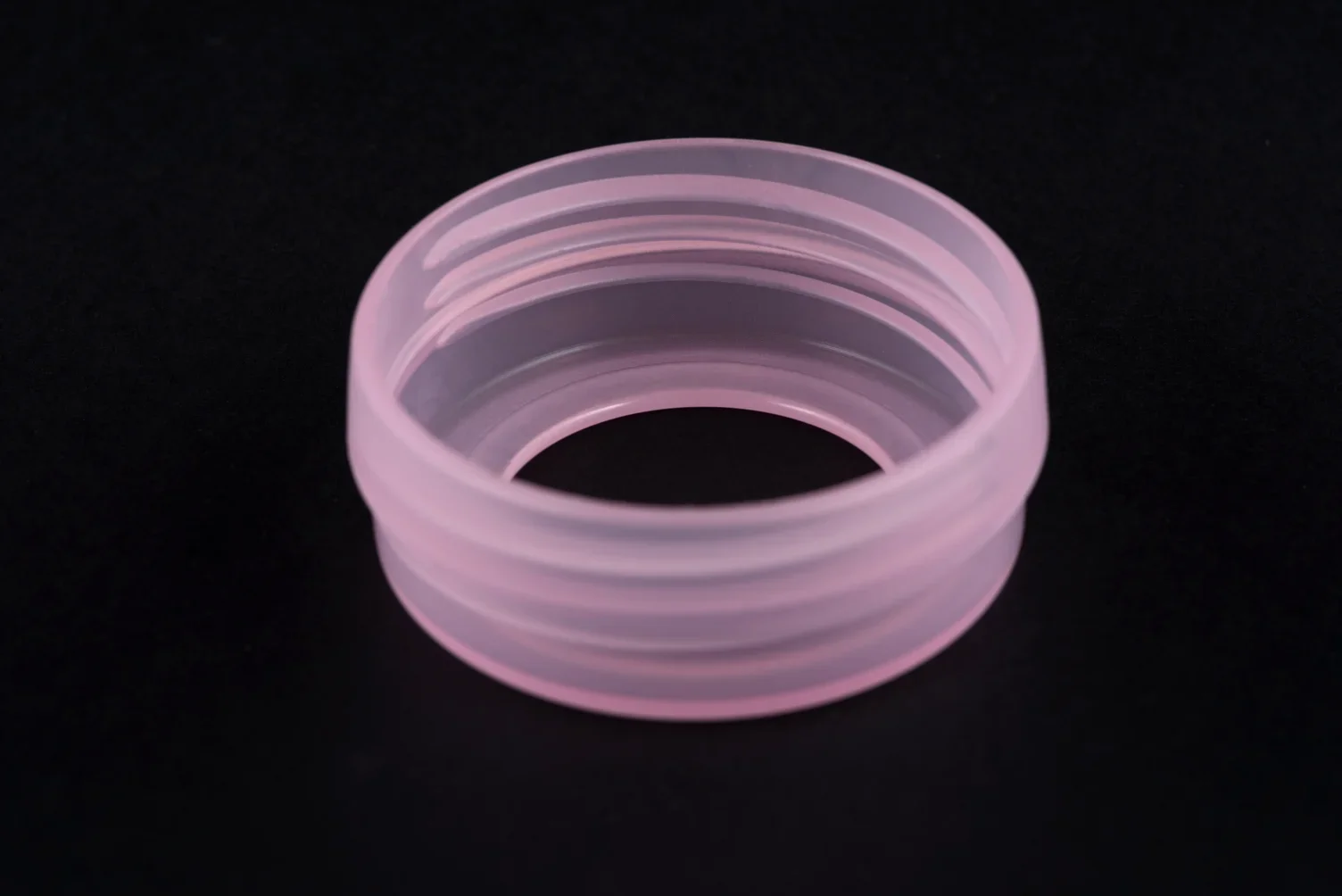

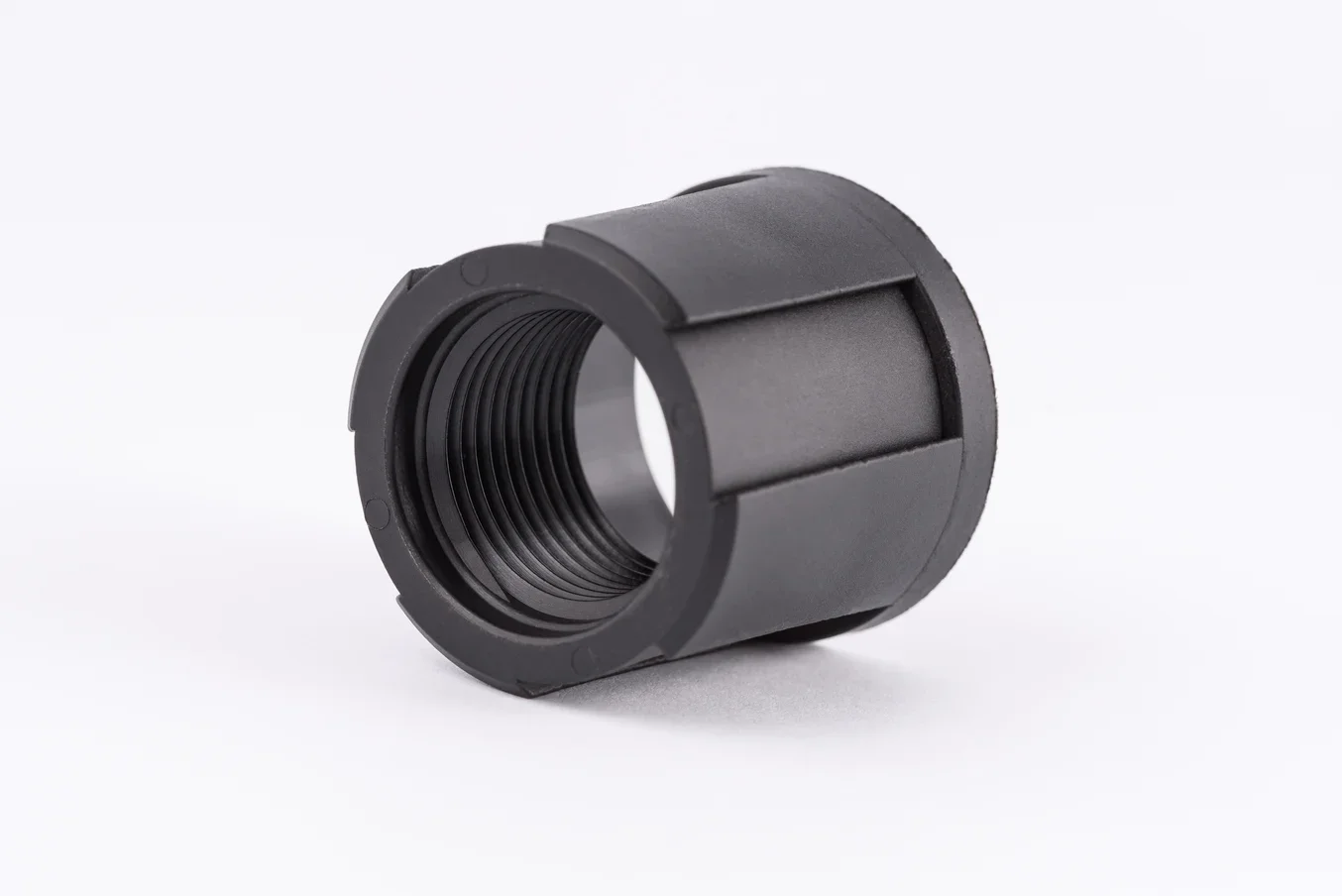

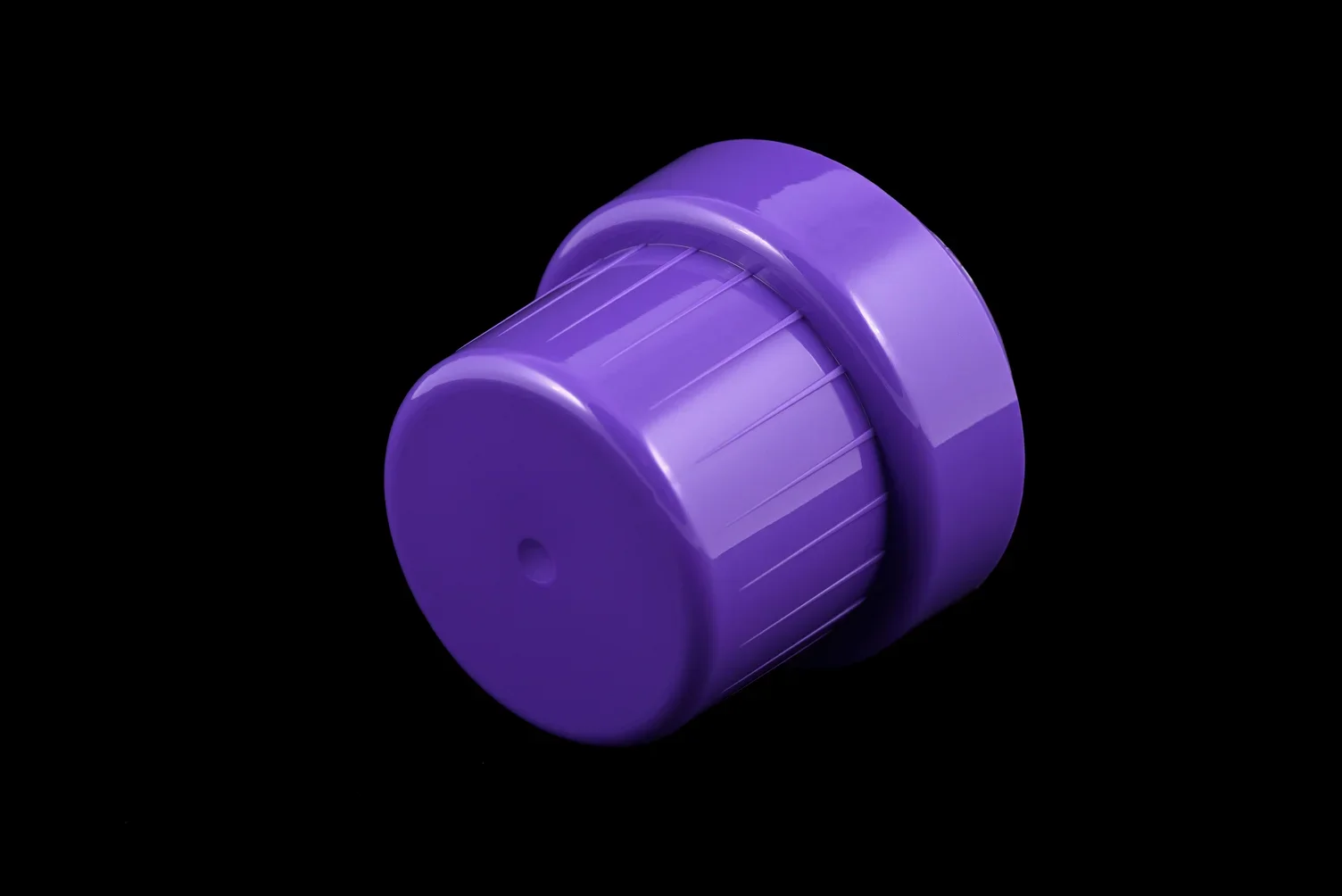

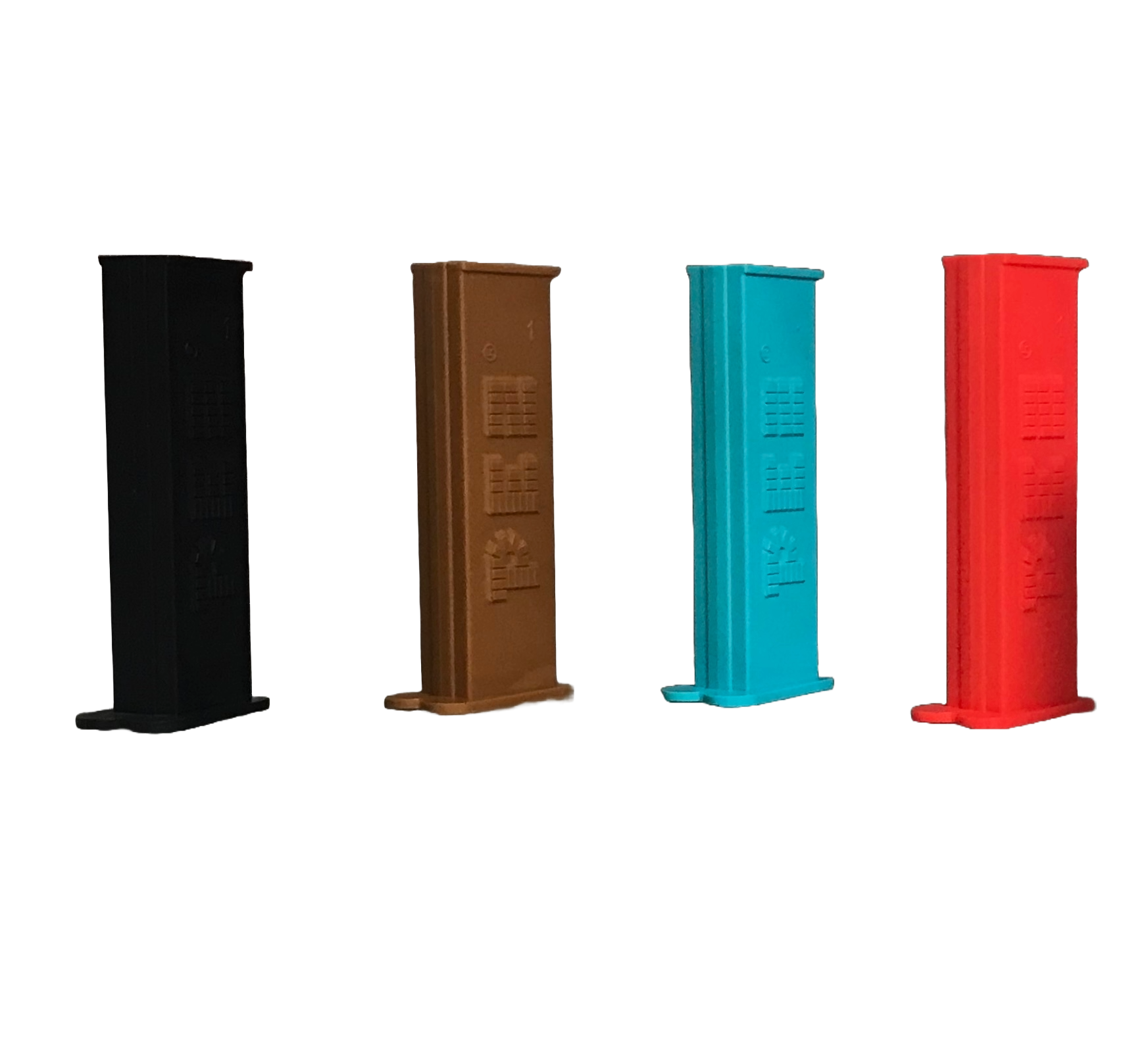

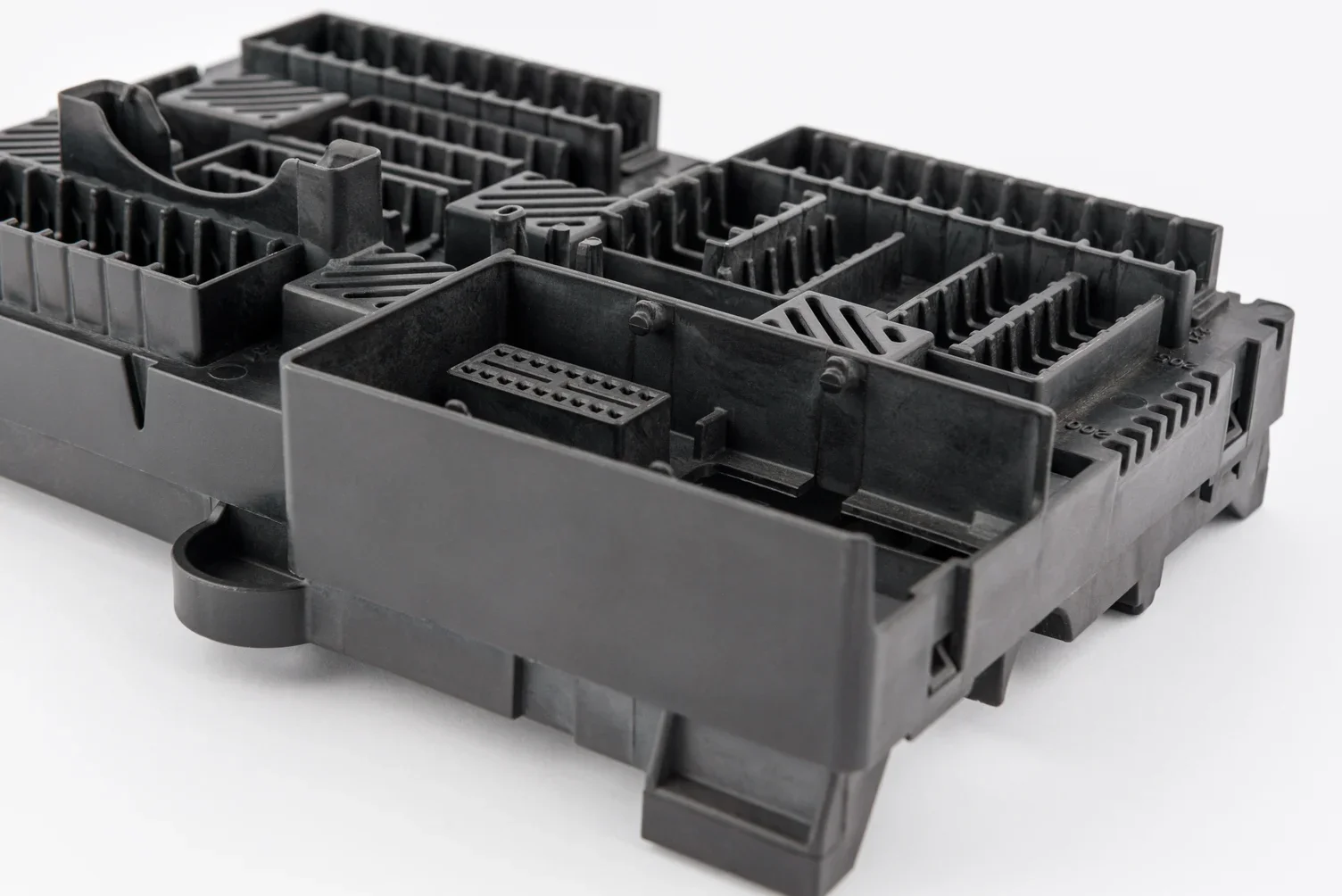

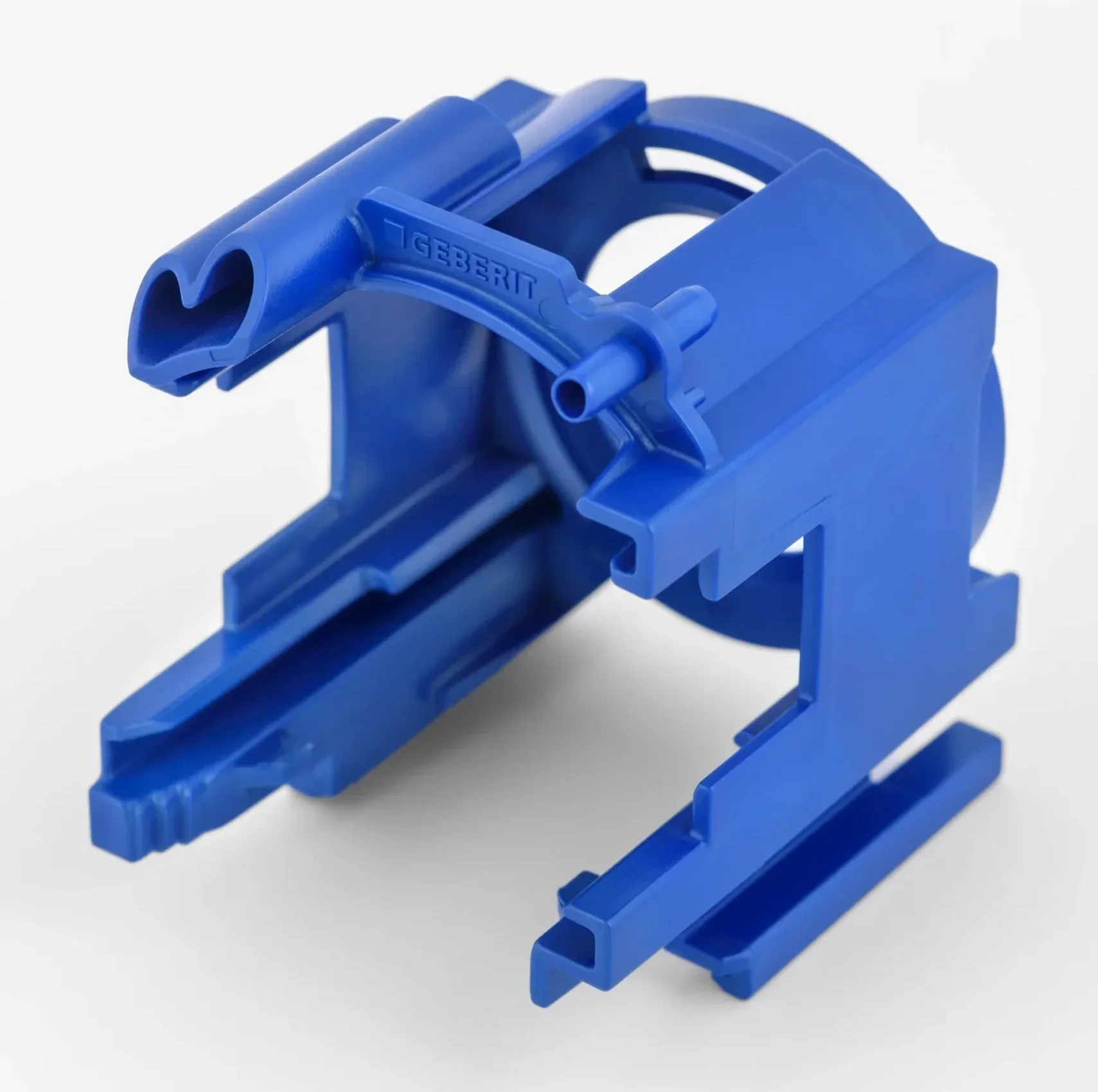

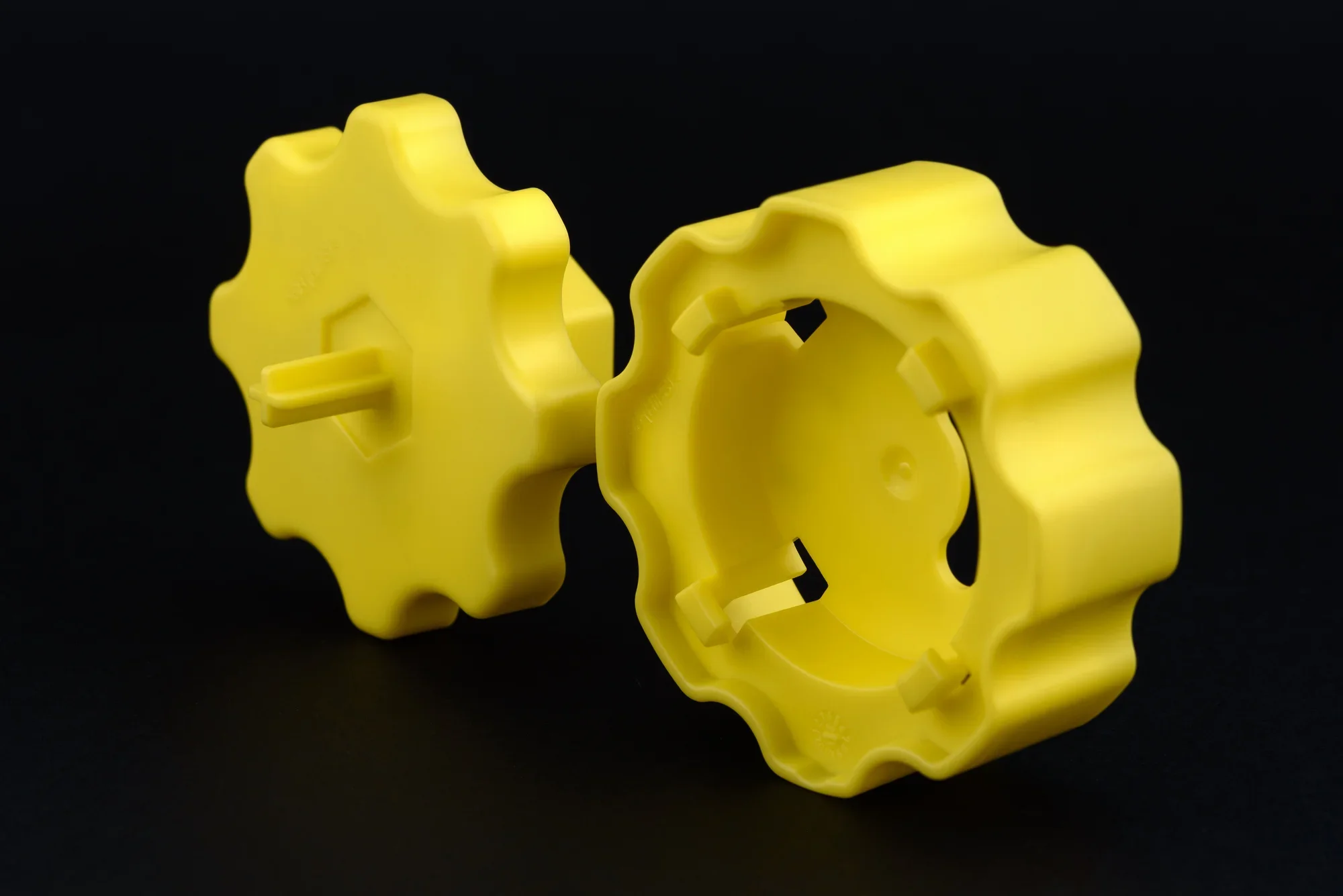

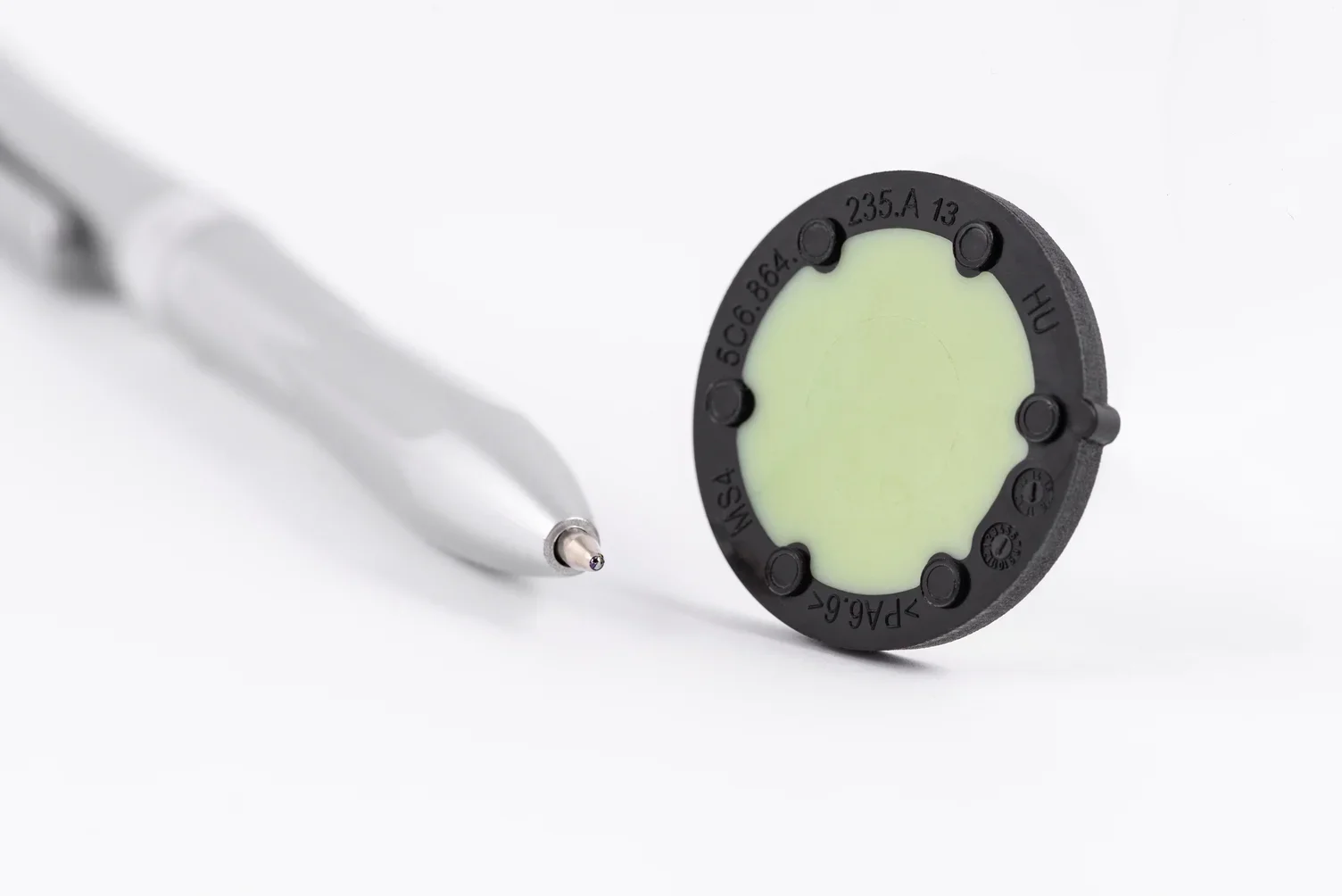

Examples of our high-quality Plastic Injection Mould components across a variety of industries

Examples of our high-quality 2K & Overmoulded Components across a variety of industries

Industries That Rely on Our Plastic Moulding Expertise

-

Automotive

Interior and exterior components, functional housings, fasteners, clips, and assembly features produced with stable cycle times and high dimensional accuracy.

-

Consumer Goods & Packaging

Closures, dispensing components, reusable products, threaded plastic parts, and custom consumer items with high-quality finishes and consistent fit.

-

Medical & Laboratory

Moulds and ready components for diagnostic devices, labware, sampling equipment, and demanding medical-grade applications that require accuracy, hygiene, and consistent repeatability.

-

Industrial Machinery & Equipment

Durable plastic parts, multi-component assemblies (2K/3K), technical mouldings, and parts used in tooling systems, machine accessories, and mechanical assemblies.

-

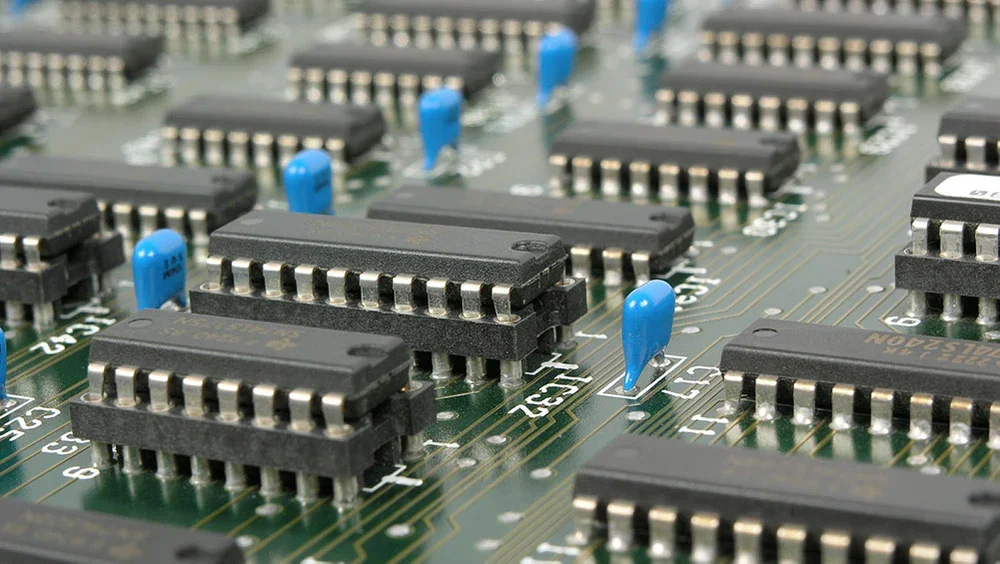

Electronics

Precision housings, casings, inserts, and overmoulded components for electrical and electronic products where fit, insulation and dimensional stability are essential.

-

Baby Products

Safe, hygienic and reliable components such as pacifiers, bottle accessories, and small-form injection moulded items produced to meet strict safety expectations.

-

Household Appliances

Plastic parts for dishwashers, washing machines, and small domestic appliances, including filters, housings, clips and structural components.

-

Defence & Security

Ruggedised polymer parts used in tactical, automotive, and field applications requiring durability under pressure.

-

Energy & Power Generation

Plastic housings and fittings for energy systems and equipment.

Our Process

We’re here to support your next project, from concept to delivery.

Whether you need precision-machined components, tooling solutions, or custom parts, our team is here to help.

We’ll review your requirements carefully and provide accurate pricing with dependable lead times for your project.